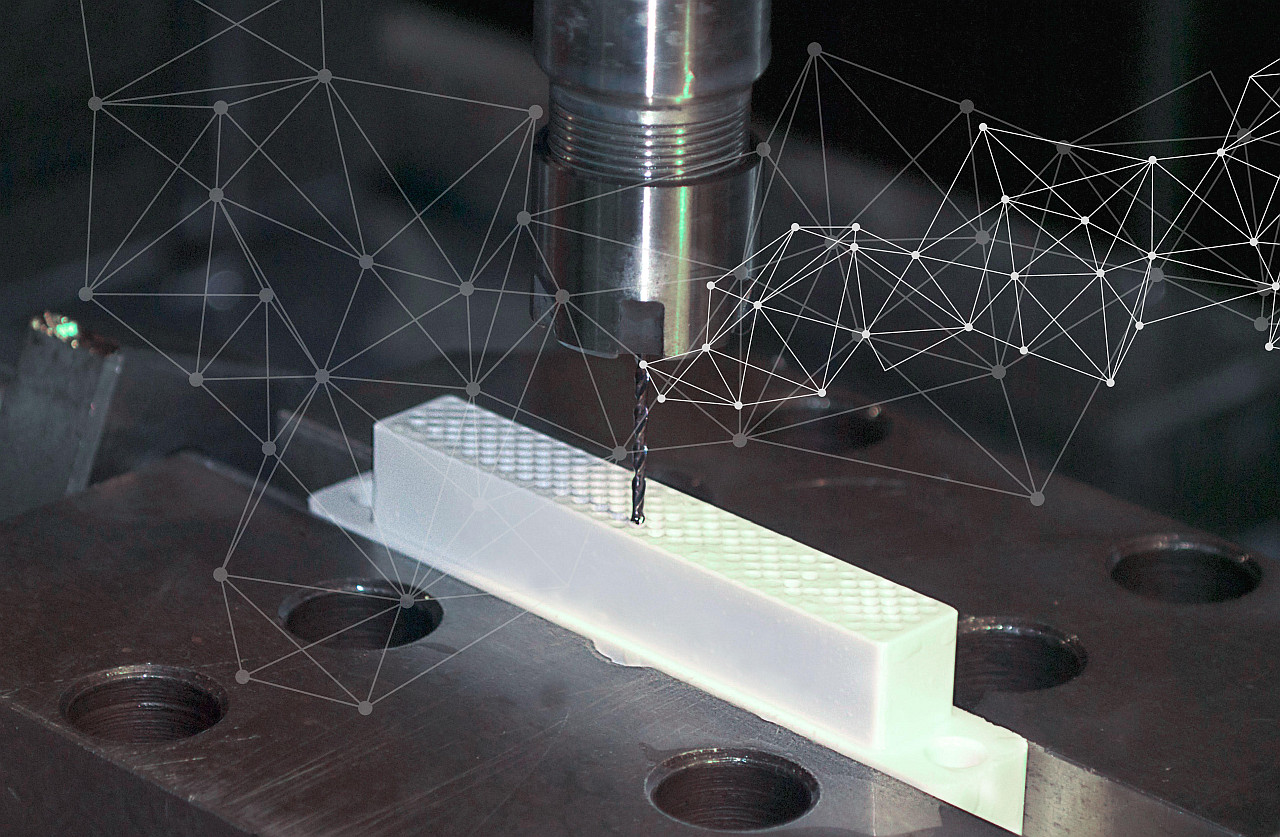

Micromachining and the importance of “working as a system”

Micromachining challenges and opportunities in the world of miniaturization.

The success of micro tool machining depends on the synergy between machine tool, tooling, fixtures and cutting fluid. The miniaturization of manufactures and the design of complex and precise geometric shapes are generating a global market interested in the production of parts with micro geometric shapes. Micro tool machining follows two approaches: machining on very small parts and machining with high geometric constraints. Micro production technologies can be derived from macro ones or be specific, such as diamond machining and laser machining. Critical issues in the tool involve deformation, thermal deformation, and surface quality, making attention to detail in coolant lubrication and system optimization essential.

Find out more by reading the article in Meccanicanews:

Find out more by reading the article in Meccanicanews: