Mechanical properties: comparison between polymers and metals

How plastics are replacing metals in high-tech industries

Polymeric materials are increasingly being used to replace metals in multiple applications, including in markets characterized by high technology content such as aerospace, the renewable energy sector, automotive, oil and gas, the chemical industry, the medical and pharmaceutical sector, the food processing and packaging industry, and the electronics and semiconductor sector.

Plastic materials can improve the performance of components and systems through

- Reduction of weights and inertia

- Absence of corrosion, high resistance to chemical attack

- Low friction and low wear coefficient even in the absence of lubrication

- Quiet operation

- Thermal and electrical insulation

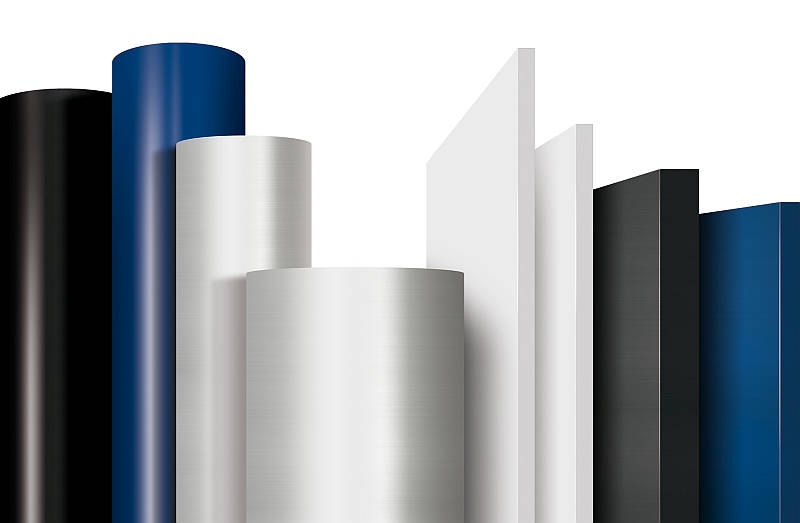

The market provides us with many dozens of different semi-finished plastic products (bars, sheets and tubes) suitable for tooling that can replace metals bringing advantages in various applications.

The following table compares schematically the mechanical properties of some polymers and metals*.

| Properties | U.M. | UHMW PE | PA6 G | PEEK | Bronze | Steel | Aluminum |

|---|---|---|---|---|---|---|---|

| Density | g/cm³ | 0.96 | 1.15 | 1.31 | 8.8 | 7.8 | 2.7 |

| Tensile yield stress | MPa | 23 | 80 | 100 | 150 | 300 | 200 |

| Relative strength to weight | Acciaio = 1 | 0.62 | 1.85 | 1.98 | 0.44 | 1.00 | 1.93 |

| Elastic modulus | MPa | 1100 | 3200 | 4200 | 110000 | 220000 | 70000 |

| Coefficient of linear thermal expansion | 10⁻⁵ K⁻¹ | 18 | 12 | 5 | 1.8 | 1.7 | 2.4 |